ZEISS CONTURA enables you to be prepared today for the measurement requirements of tomorrow: The new generation is equipped with the mass technology and, thanks to a common interface, enables simple switching between different sensor technologies in just a few simple steps. In addition to innovative options such as measuring in four axes using a flexible rotary table, an automated probe changing system or the HTG option (for larger temperature ranges), the device also stands for first-class performance, ergonomics and future security.

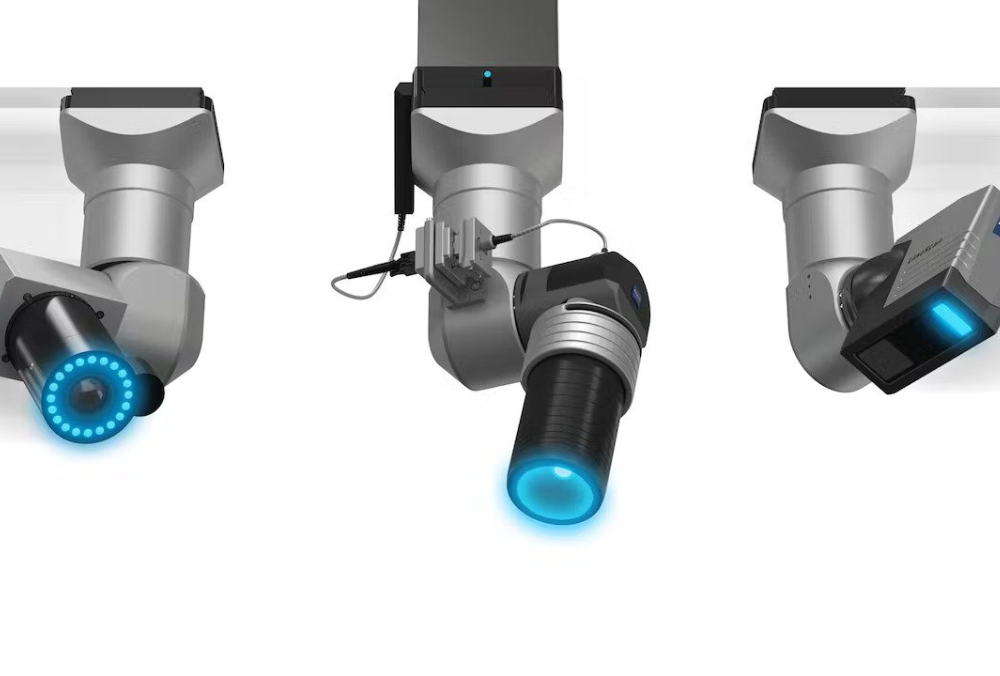

Versatility with mass technology

ZEISS CONTURA comprises an extensive range of sensors and thus offers the right sensor or sensor system for every application and every requirement. With the mass technology, a large number of ZEISS sensors can be operated with high precision and quickly replaced on the same measuring instrument: Sensors with an articulating probe holder or fixed probe configuration, optical or tactile, passive or active – this is how ZEISS CONTURA achieves maximum flexibility.