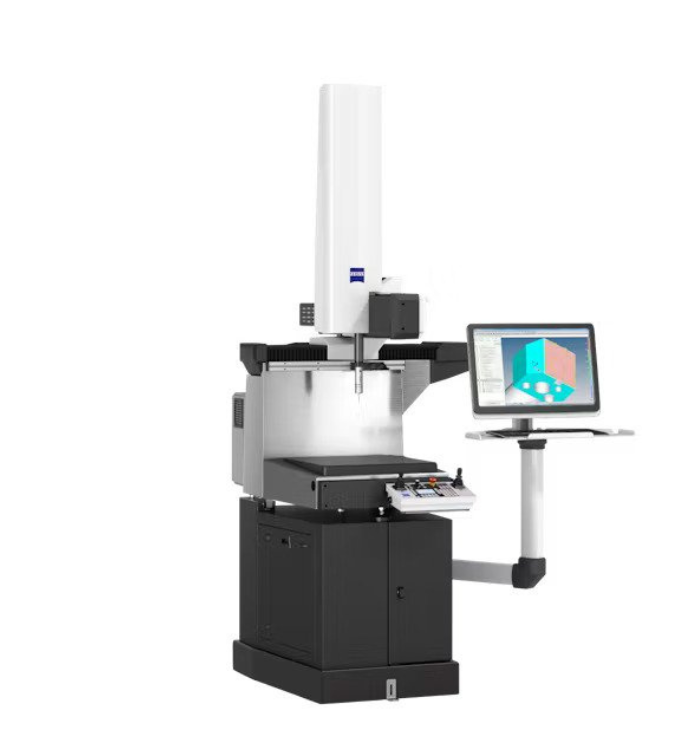

Quality assurance is demanding and CMM requirements are high – especially in the production environment. ZEISS DuraMax combines robustness, precision and efficiency, making it the perfect choice for at-line measurement directly in your production hall. ZEISS DuraMax is not deterred by harsh environmental conditions and withstands even high temperatures. In conjunction with the ZEIS VAST XXT-Sensor it enables fast single-point measurements as well as scanning of contours and free-form surfaces, making fixed gauges superfluous.

Even less temperature-sensitive, even more robust

ZEISS DuraMax HTG offers the widest temperature range with the highest temperature gradient and can be operated both at the production site and in automation systems. This provides more flexibility as you can perform your measurement tasks with even more resistance to environmental influences.

Highlights

- Precise measurement at high temperatures

- Zerodur scales for smallest possible heat expansion

- Temperature sensors for workpiece temperature correction

- Additional filter pads in the X- and Y-axis to protect against dirt and dust