The perfect symbiosis of seeing and touching

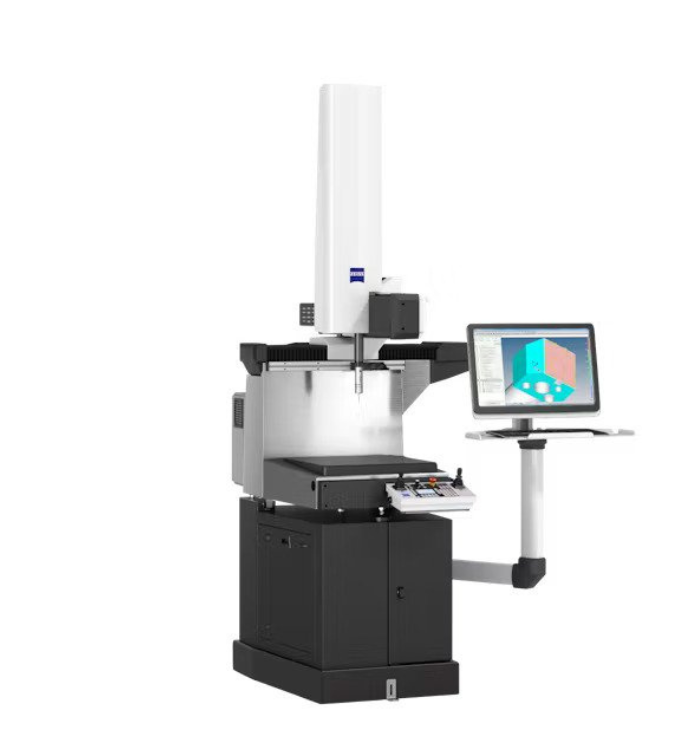

ZEISS O-INSPECT

ZEISS O-INSPECT multi-sensor measuring machines enable to optimally measure each characteristic in compliance with ISO-10360 – optically or by contact.

Your advantages:

✓ Large visual field with high image definition

✓ Quick and precise 3D tactile measurements

✓ Optical measurements for sensitive surfaces

✓ Increased reliability in less time